About Project

SAFEBUILT Industries Private Limited, India proposes to undertake the project activity which entails manufacturing of the Autoclaved Aerated Concrete Blocks hereafter referred to as (AAC) blocks. AAC blocks will be manufactured through an energy efficient brick manufacturing technology supplied by Dongyue Group, China or any other identical hardware and technology provider from China, Germany, Netherlands or India. All details regarding the primary production line machinery – hardware and technology, emissions related calculations data and carbon credit opportunities will be provided by primary production line hardware and technology supplier.

Red Bricks Compared to AAC Blocks

AAC blocks are lighter biult easy to carry and construction are safer to live in. These structures are more cost effective in terms of both time and money when stacked against each other. If we are to compare conventional red ricks with AAC blocks they would compare as below.

Why AAC?

AAC blocks are lighter in weight and construct safer structures. Although the cost of one AAC block is more than conventional brick but when compared to the net cost of construction, use of AAC works out ~35% cheaper.

Hazadrous Waste Disposal

Consumes Fly ash, which is a big problem for thermal power plants to dispose. It is environment friendly, because of no need of burning.

Insulation

Higher strength, best thermal insulation & excellent sound absorption, vibration resistance compared to red bricks.

Resistance

The AAC product’s lightweight and easy workability means that is very quick to install on site and transportation with lesser breakage.

Cost Effective

AAC blocks made walls can be left exposed (without Plaster) and gains strength over time. It saves structural cost by 35% and recycling of breakage, rejects also.

Durable

AAC products are not affected by harsh climatic conditions and will not degrade under normal atmospheric conditions.

Eco Friendly

AAC Block does not have any toxic substances nor does it emit odors. Its production, management and disposal do not represent any health risks or damage to the environment. Its production process develops non-toxic gases.

Strength

AAC blocks are bigger in size then conventional bricks, resulting in lesser number of joints. Less joints result in lesser quantity of mortar required and greater strength.

Quick Installation

The AAC product’s lightweight and easy workability means that is very quick to install on site and transportation with lesser breakage.

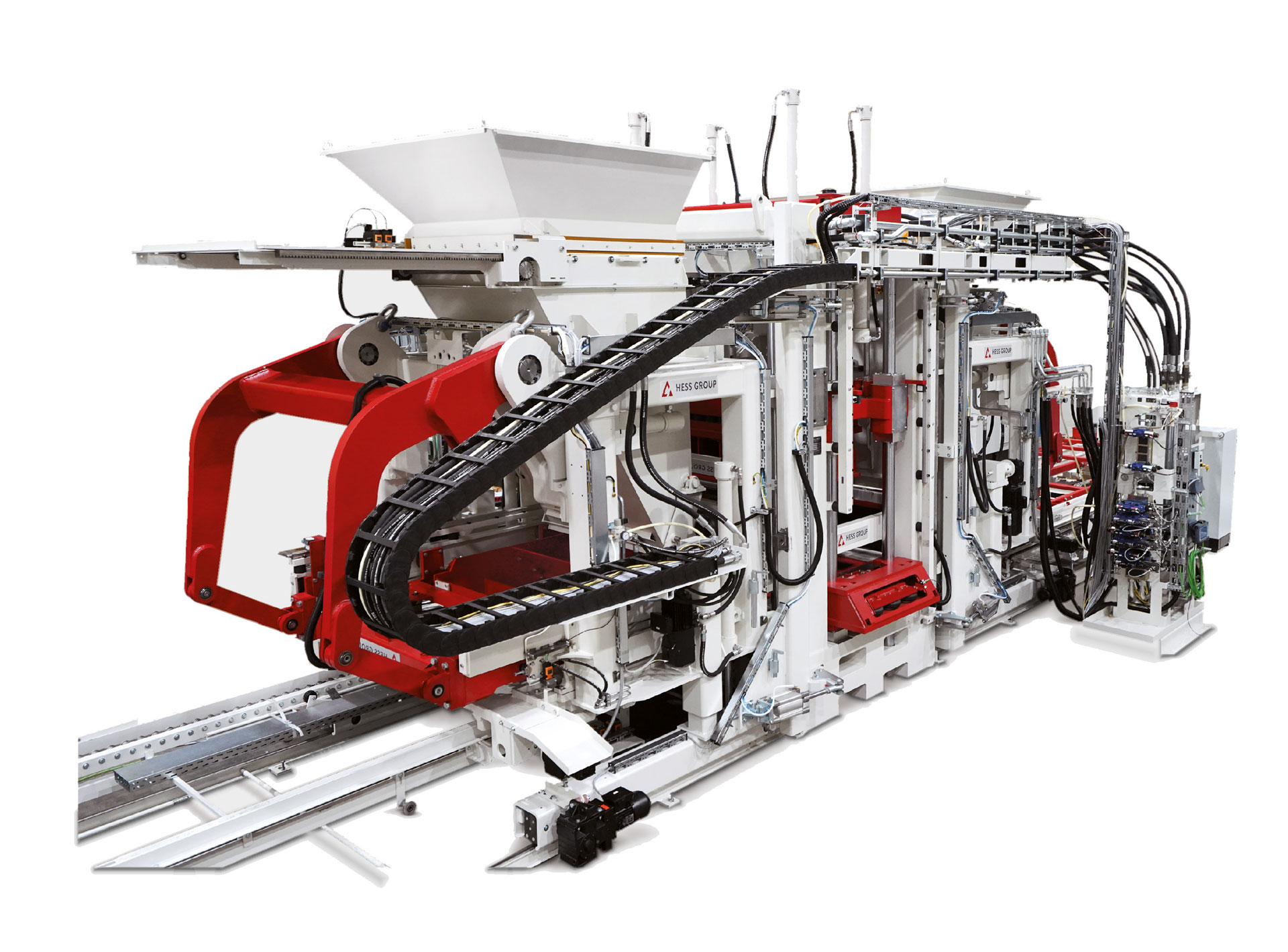

Manufacturing Process

AAC is Autoclaved Aerated Concrete. The blocks are made to aerate by creating a reaction between silica in base material such as Fly Ash, Active Hydrated Lime or Calcium Oxide (CaO) and grounded Aluminium Powder. The block hardness is achieved by cement strength and instant curing mechanism by autoclaving. Fused Gypsum also known as Calcium sulphate Hydrate (CaSO4 2H2O) acts as a long-term strength gainer.

Process

Raw Materials Preparation

The inspection of raw materials happens before they enter our manufacturing plant. These proceed to the next stage only when their quality is ascertained. Cement and Lime are stored to prevent the moisture. To ensure this, there is a separate pneumatic-based unloading system for raw materials.

Explore More

Dosing and Mixing

Safebuilt AAC Blocks are made of Fly-Ash Slurry, Ordinary Portland Cement, Quick Lime, Gypsum (Pop) and Aluminum Powder. The desired volume of each raw material is mixed by using a precise batching system for ensuring the consistency of every batch. Based on the respective test results, the material is batched accordingly to eliminate the variation in the batch quality.

Explore More

Pouring and Casting

Each raw material is accurately and uniformly poured into big sized mold boxes using an automated mobile mixer. After the batches are poured into molds, they are monitored by our highly skilled and dedicated quality team to ensure its quality matches with the desired parameters.

Explore More

Cutting and Grouping

Porous Green Cake is then cut into the required size using high tensile, low thickness wires to provide sharp and precise edges to the Safebuilt AAC Blocks. The automated system precisely cuts the AAC Block vertically and horizontally for providing accurate dimensions.

Explore More

Autoclaving

Post cutting, the Porous Green Cake is subjected to the steam curing process in Autoclaves for 10-12 hours. This provides 12 bars of steam pressure at a temperature of 190-210. This Autoclaving process is responsible for the physical and chemical properties of Safebuilt AAC Blocks.

Explore More

Dispatch

This is the final step in the manufacturing process of Ecorex AAC Blocks. After Autoclaving, these AAC Blocks are separated with the help of automated Grab and Shift assembly process to minimize human intervention. After separation, the Final Product is then transferred to the stock yard using a chain conveyor system. After this, the Final Product is ready for dispatch.

Explore More